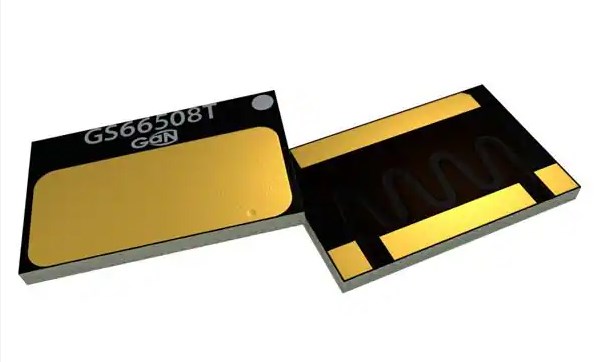

One technological advancement that holds great promise is the implementation of GS66508T—an electronic component designed to revolutionize manufacturing operations. With its advanced features and precision control, GS66508T has the potential to significantly impact efficiency and productivity in the manufacturing sector.

Overview of GS66508T

GS66508T

GS66508T is an advanced electronic component designed to enhance efficiency and productivity in manufacturing processes. It offers a wide range of features and functions that make it a valuable asset for industries striving for improved operational performance.

Key benefits

- High Performance: With its cutting-edge design, GS66508T delivers exceptional performance, enabling faster and more efficient manufacturing processes. It can handle high workloads and complex operations with ease.

- Quick Response Time: It ensures near-instantaneous response times, minimizing delays and bottlenecks in production lines. It enables real-time control and synchronization of various manufacturing stages, optimizing workflow efficiency.

- Precision Control: This component offers precise control over critical processes, resulting in improved accuracy and consistency. It ensures that each manufacturing step is executed with the highest level of precision, minimizing errors and rework.

- Energy Efficiency: It is designed to minimize energy consumption without compromising performance. By optimizing power usage and reducing waste, it helps lower operational costs and promotes sustainable manufacturing practices.

Potential applications

1) Automotive Manufacturing

GS66508T can be utilized in automotive assembly lines to enhance efficiency, precision, and quality control during the production of vehicles.

2) Electronics and Semiconductor Industry

In the electronics and semiconductor manufacturing processes, GS66508T can optimize resource allocation, streamline operations, and improve overall productivity.

3) Pharmaceutical Production

The component’s high performance and precision control make it suitable for pharmaceutical manufacturing, where accuracy and efficiency are paramount.

4) Food and Beverage Processing

It can play a crucial role in enhancing efficiency and productivity in food and beverage processing plants by ensuring accurate and timely control over various stages of production.

Efficiency Enhancement with GS66508T

Specific ways to improve efficiency in manufacturing processes

- Real-time Monitoring and Control: The component enables real-time monitoring and control of critical parameters, allowing for immediate adjustments and optimizations. This capability minimizes downtime and ensures optimal performance.

- Process Automation: It supports process automation, reducing the need for manual intervention and streamlining operations. It automates repetitive tasks, freeing up human resources to focus on more complex and value-added activities.

- Advanced Data Analytics: With its data analytics capabilities, GS66508T can collect and analyze vast amounts of manufacturing data. It provides valuable insights that help identify areas for improvement, optimize resource allocation, and enhance overall productivity.

How it optimizes resource allocation, reduces waste, and streamlines operations

By providing real-time insights into resource utilization, GS66508T allows manufacturers to allocate resources effectively. This helps avoid overutilization or underutilization of assets, optimizing their usage and reducing costs.

Through precise control and automation, GS66508T minimizes material waste in manufacturing processes. It ensures accurate measurements, reduces scrap rates, and improves overall yield, resulting in cost savings.

It streamlines operations by synchronizing different stages of manufacturing, eliminating bottlenecks, and optimizing workflow. It enables seamless coordination between different machines and processes, improving overall throughput and reducing cycle times.

Productivity Boost with GS66508T

Impact of GS66508T on overall productivity in manufacturing

GS66508T is a game-changing electronic component that can significantly boost overall productivity in manufacturing. Its advanced features and functions enable automation, reduce downtime, and increase output, revolutionizing the efficiency of manufacturing processes.

Ability to automate tasks, reduce downtime, and increase output

By incorporating GS66508T into manufacturing operations, tasks can be automated, reducing the need for manual intervention. Repetitive and time-consuming tasks that were previously performed by workers can now be handled efficiently. This automation frees up human resources to focus on more complex and value-added activities, ultimately increasing productivity.

GS66508T enables real-time monitoring of critical parameters and immediate adjustments when necessary. With its quick response time, it minimizes downtime caused by equipment failures or maintenance issues. The component also ensures precise control over manufacturing processes, minimizing errors and rework. By streamlining operations and eliminating bottlenecks, it enables manufacturers to achieve higher output levels and maximize productivity.

How GS66508T enables real-time monitoring and data-driven decision making

One of the key advantages of GS66508T is its ability to facilitate real-time monitoring. It collects vast amounts of manufacturing data and provides valuable insights that allow for data-driven decision making. Manufacturers can analyze this data to identify areas for improvement, optimize resource allocation, and enhance overall productivity. With it companies can make informed and timely decisions that positively impact productivity and operational efficiency.

Cost Savings and ROI

Potential cost savings associated with using GS66508T

Reduced Labor Costs:

It automates various tasks, minimizing the need for manual labor. By streamlining processes, it reduces the workforce required and decreases associated labor costs.

Minimized Production Errors:

GS66508T’s precise control ensures accurate measurements and execution of manufacturing processes. This reduces errors and the need for rework, resulting in cost savings by reducing material waste and labor costs.

Enhanced Efficiency:

With real-time monitoring and data analysis capabilities, GS66508T helps optimize resource utilization. It identifies bottlenecks and inefficiencies, allowing manufacturers to allocate resources effectively and eliminate unnecessary waste, leading to cost reductions.

Improved Quality Control:

GS66508T’s advanced features enable manufacturers to maintain consistent product quality. By detecting deviations from desired specifications and making automatic adjustments, it reduces product defects and associated costs.

Energy Savings:

GS66508T can monitor energy consumption during manufacturing processes and identify opportunities for energy-saving initiatives. By optimizing energy usage, manufacturers can reduce electricity costs and support environmental sustainability.

How does it work

1. Minimizing Production Errors

One of the key advantages is its ability to minimize production errors. Through its advanced sensors and real-time data analysis, it can detect any anomalies or deviations in the manufacturing process. By promptly identifying and rectifying errors, companies can avoid costly rework, saving both time and money. This not only ensures a higher quality end product but also enhances overall operational efficiency.

2. Reducing Rework

Rework is a common issue in manufacturing operations that can consume valuable resources and hinder productivity. GS66508T helps in reducing rework by providing accurate and reliable data throughout the production cycle. This enables manufacturers to identify any potential errors or defects early on, allowing for immediate corrective actions. By minimizing rework, companies can save on additional labor costs, materials, and production time, resulting in significant cost savings.

3. Optimizing Resource Utilization

Another significant cost-saving benefit of implementing GS66508T is the optimization of resource utilization. By providing real-time insights into the production process, this technology allows manufacturers to identify any inefficient resource allocation. Whether it’s excessive energy consumption, underutilized machinery, or human errors, GS66508T enables companies to optimize resource allocation and reduce wastage.

Challenges and Considerations in Implementing GS66508T

Potential cost implications and investment required

Implementing GS66508T involves certain costs, including the initial investment in the technology and any required infrastructure upgrades. It is essential for companies to carefully assess these cost implications and evaluate whether the potential savings outweigh the expenses. Conducting a thorough cost analysis and considering the long-term benefits can help organizations make informed decisions.

Compatibility issues or limitations

Compatibility issues and limitations may arise when implementing GS66508T in different manufacturing environments. Companies need to ensure that this technology can seamlessly integrate into their existing systems and processes.

In some cases, modifications or adaptations might be required to ensure compatibility. Thorough testing and consultation with technology providers can help address these compatibility issues and ensure a smooth implementation process.

Need for proper training and education

To ensure the successful implementation of GS66508T, proper training and education are essential. The technology may require operators and employees to acquire new skills or knowledge to effectively utilize its features. Lack of proper training can result in underutilization or misuse of it, limiting its potential benefits. Providing comprehensive training programs and educational resources will empower employees and enable them to leverage the technology to its fullest potential.

Conclusion

As the manufacturing industry strives for continuous improvement, the adoption of GS66508T emerges as a game-changer. By embracing the power of GS66508T, manufacturers can unlock new levels of efficiency and productivity, paving the way for future success in the ever-evolving world of manufacturing.